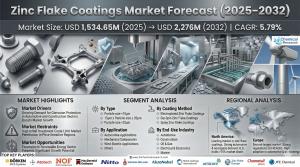

Zinc Flake Coatings Market to Reach USD 2.27 Billion by 2032, Driven by 5.79% CAGR and Rising Anti-Corrosion Demand

Zinc flake coatings market set to grow from USD 1.53B in 2025 to USD 2.27B by 2032, driven by eco-friendly corrosion protection demand.

As the market expands from USD 1.53 billion to USD 2.27 billion by 2032, the 5.79% CAGR highlights growing reliance on eco-safe, high-performance corrosion protection.”

PUNE, MAHARASHTRA, INDIA, December 11, 2025 /EINPresswire.com/ -- Zinc Flake Coatings Market, valued at USD 1,534.65 million in 2025, is projected to reach USD 2,276 million by 2032, expanding at an impressive 5.79% CAGR. This steady rise reflects the critical role zinc flake technologies now play in modern industries seeking durable, eco-friendly, and high-performance corrosion protection systems.— 24ChemicalResearch

Zinc flake coatings, composed of ultra-fine zinc and aluminum flakes within an inorganic binder, deliver superior barrier protection compared to traditional zinc plating. Their ability to resist corrosion, even in extreme environments, positions these coatings as essential materials across automotive, construction, marine, energy, and industrial machinery sectors. The market’s upward momentum is further supported by evolving global regulations that are pushing industries toward chrome-free, environmentally safe coating technologies.

➤ 𝗘𝘅𝗽𝗹𝗼𝗿𝗲 𝘁𝗵𝗲 𝗳𝘂𝘁𝘂𝗿𝗲 𝗼𝗳 𝘁𝗵𝗲 𝗺𝗮𝗿𝗸𝗲𝘁! 𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝗼𝘂𝗿 𝗦𝗮𝗺𝗽𝗹𝗲 𝗥𝗲𝗽𝗼𝗿𝘁 𝗳𝗼𝗿 𝗸𝗲𝘆 𝘁𝗿𝗲𝗻𝗱𝘀 𝗮𝗻𝗱 𝗮𝗻𝗮𝗹𝘆𝘀𝗶𝘀: https://www.24chemicalresearch.com/download-sample/247086/Zinc-flake-coatings-market

𝐒𝐮𝐩𝐞𝐫𝐢𝐨𝐫 𝐂𝐨𝐫𝐫𝐨𝐬𝐢𝐨𝐧 𝐃𝐞𝐟𝐞𝐧𝐬𝐞 𝐃𝐫𝐢𝐯𝐞𝐬 𝐌𝐚𝐫𝐤𝐞𝐭 𝐀𝐝𝐨𝐩𝐭𝐢𝐨𝐧

Industries today are under immense pressure to extend asset lifespan, reduce maintenance downtime, and comply with environmental protection standards. Zinc flake coatings meet these requirements by offering:

• High corrosion resistance without hydrogen embrittlement

• Uniform, controllable coating layers

• Compatibility with fasteners, brake components, and high-stress mechanical parts

• Outstanding performance under salt spray and cyclic corrosion tests

These advantages have led to rapid adoption across sectors where reliability, safety, and performance are non-negotiable.

𝐒𝐞𝐠𝐦𝐞𝐧𝐭 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬

◘ 𝗕𝘆 𝗧𝘆𝗽𝗲

The particle size <15μm segment leads the market due to its ability to deliver smoother, uniform finishes and superior high-performance corrosion resistance. These fine-particle systems are preferred in automotive and critical industrial applications.

◘ 𝗕𝘆 𝗖𝗼𝗮𝘁𝗶𝗻𝗴 𝗠𝗲𝘁𝗵𝗼𝗱

Electroplated zinc flake coatings dominate, supported by their cost-effectiveness, high scalability, and consistent layer deposition. Dip-spin coatings follow closely, especially for complex-shaped fasteners.

◘ 𝗕𝘆 𝗔𝗽𝗽𝗹𝗶𝗰𝗮𝘁𝗶𝗼𝗻

The automotive segment holds the largest share, driven by increasing use of zinc flake systems in underbody components, brake systems, bolts, nuts, and structural fasteners.

◘ 𝗕𝘆 𝗘𝗻𝗱-𝗨𝘀𝗲 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝘆

The automotive industry remains the top consumer, while construction, oil & gas, marine, and E&E industries continue to expand their use of long-lasting coating technologies.

➤ 𝗖𝗵𝗲𝗰𝗸 𝗢𝘂𝘁 𝗢𝘂𝗿 𝗟𝗮𝘁𝗲𝘀𝘁 𝗔𝗻𝗮𝗹𝘆𝘀𝗶𝘀 𝗥𝗲𝗽𝗼𝗿𝘁: https://www.24chemicalresearch.com/reports/247086/zinc-flake-coatings-market

𝗭𝗶𝗻𝗰 𝗙𝗹𝗮𝗸𝗲 𝗖𝗼𝗮𝘁𝗶𝗻𝗴𝘀 𝗶𝗻 𝘁𝗵𝗲 𝗔𝗴𝗲 𝗼𝗳 𝗘𝗹𝗲𝗰𝘁𝗿𝗶𝗳𝗶𝗰𝗮𝘁𝗶𝗼𝗻

The expansion of EV and hybrid vehicle production is unlocking new opportunities for zinc flake technology. Lightweight components, battery housings, connectors, and structural fasteners require corrosion resistance without adding weight, an area where zinc flake coatings outperform traditional galvanization. This trend is expected to significantly boost demand through 2032.

𝐑𝐞𝐠𝐢𝐨𝐧𝐚𝐥 𝐎𝐮𝐭𝐥𝐨𝐨𝐤

⁍ 𝗡𝗼𝗿𝘁𝗵 𝗔𝗺𝗲𝗿𝗶𝗰𝗮

North America’s demand is fueled by strict corrosion protection standards in automotive, aerospace, and heavy equipment sectors. The U.S. holds more than 75% of regional consumption, supported by environmentally compliant water-based coating technologies.

⁍ 𝗘𝘂𝗿𝗼𝗽𝗲

Europe remains a major hub for advanced zinc flake systems, with strong adoption in wind turbines, EV manufacturing, and industrial machinery. Strict EU REACH compliance continues to shift manufacturers toward chrome-free, high-strength formulations.

⁍ 𝗔𝘀𝗶𝗮-𝗣𝗮𝗰𝗶𝗳𝗶𝗰

Asia-Pacific is the fastest-growing region, expected to surpass USD 500 million by 2032. Growth is driven by China’s massive manufacturing output, India’s infrastructure boom, and increasing automotive production across Japan and South Korea.

⁍ 𝗦𝗼𝘂𝘁𝗵 𝗔𝗺𝗲𝗿𝗶𝗰𝗮

Moderate growth is observed due to adoption by automotive OEMs and mining equipment manufacturers. Brazil dominates regional usage, supported by industrial expansion and imports of high-performance coating systems.

⁍ 𝗠𝗶𝗱𝗱𝗹𝗲 𝗘𝗮𝘀𝘁 & 𝗔𝗳𝗿𝗶𝗰𝗮

GCC infrastructure megaprojects and oil & gas developments fuel regional demand. The UAE and Saudi Arabia lead adoption for marine and industrial components requiring extreme corrosion resistance.

𝗥𝗶𝘀𝗶𝗻𝗴 𝗡𝗲𝗲𝗱 𝗳𝗼𝗿 𝗘𝘅𝘁𝗲𝗻𝗱𝗲𝗱 𝗖𝗼𝗺𝗽𝗼𝗻𝗲𝗻𝘁 𝗟𝗶𝗳𝗲𝗰𝘆𝗰𝗹𝗲𝘀 𝗔𝗰𝗿𝗼𝘀𝘀 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝗶𝗲𝘀

Infrastructure projects, renewable energy assets, and industrial machinery now demand coatings that ensure multi-year durability under extreme stress. Zinc flake systems are increasingly used in wind turbines, LNG equipment, marine installations, and high-temperature industrial equipment due to their robust and long-lasting protection performance.

➤ 𝗦𝘁𝗮𝘆 𝗶𝗻𝗳𝗼𝗿𝗺𝗲𝗱 𝗱𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝗼𝘂𝗿 𝗦𝗮𝗺𝗽𝗹𝗲 𝗥𝗲𝗽𝗼𝗿𝘁 𝘁𝗼 𝘂𝗻𝗱𝗲𝗿𝘀𝘁𝗮𝗻𝗱 𝘁𝗵𝗲 𝗹𝗮𝘁𝗲𝘀𝘁 𝗺𝗮𝗿𝗸𝗲𝘁 𝘀𝗵𝗶𝗳𝘁𝘀: https://www.24chemicalresearch.com/download-sample/247086/Zinc-flake-coatings-market

𝐊𝐞𝐲 𝐏𝐥𝐚𝐲𝐞𝐫𝐬 𝐢𝐧 𝐭𝐡𝐞 𝐙𝐢𝐧𝐜 𝐅𝐥𝐚𝐤𝐞 𝐂𝐨𝐚𝐭𝐢𝐧𝐠𝐬 𝐌𝐚𝐫𝐤𝐞𝐭

🔹Dörken MKS-Systeme GmbH & Co. KG

🔹Atotech

🔹NOF Metal Coatings Group

🔹MacDermid Enthone Industrial Solutions

🔹Nitto Metal Co., Ltd.

🔹The Sherwin-Williams Company

🔹AkzoNobel N.V.

🔹Metal Coatings International Inc.

🔹Umicore Group

🔹Zinc Flake Europe GmbH

🔹Chemetall (BASF Group)

🔹JFE Chemical Corporation

🔹Others

The market is dominated by established global players with strong expertise in high-performance coatings and international distribution networks. These companies compete by innovating water-based, chrome-free formulations, enhancing production capacity, and developing advanced zinc-aluminum systems for high-load mechanical components. Continuous R&D in particle refinement, heat-resistance coatings, and environmentally compliant formulas remains at the center of competitive strategy.

𝐓𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐢𝐜𝐚𝐥 𝐄𝐯𝐨𝐥𝐮𝐭𝐢𝐨𝐧: 𝐓𝐡𝐞 𝐒𝐡𝐢𝐟𝐭 𝐓𝐨𝐰𝐚𝐫𝐝 𝐒𝐮𝐬𝐭𝐚𝐢𝐧𝐚𝐛𝐥𝐞 𝐂𝐨𝐚𝐭𝐢𝐧𝐠 𝐂𝐡𝐞𝐦𝐢𝐬𝐭𝐫𝐲

Growing regulatory pressure worldwide is accelerating the shift to VOC-free, water-based zinc flake coatings. Manufacturers are developing new binder chemistries, advanced curing systems, and low-temperature application technologies that reduce energy consumption and carbon emissions. This marks a major industry trend toward greener surface protection solutions without compromising performance.

𝐊𝐞𝐲 𝐁𝐞𝐧𝐞𝐟𝐢𝐭𝐬 𝐨𝐟 𝐏𝐮𝐫𝐜𝐡𝐚𝐬𝐢𝐧𝐠 𝐓𝐡𝐢𝐬 𝐑𝐞𝐩𝐨𝐫𝐭

• Comprehensive analysis of market opportunities from 2025–2032

• Detailed segmentation by type, application, coating method, and end-use industry

• Deep-dive assessment of regional growth drivers and restraints

• Competitive landscape and strategic positioning of major players

• Insight into emerging technologies and future product innovations

• Market size projections backed by reliable data models

• Evaluation of regulatory impacts across global markets

• Identification of high-growth investment pockets and revenue opportunities

👉 𝐆𝐞𝐭 𝐅𝐮𝐥𝐥 𝐀𝐜𝐜𝐞𝐬𝐬 𝐭𝐨 𝐭𝐡𝐞 𝐃𝐞𝐭𝐚𝐢𝐥𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭: https://www.24chemicalresearch.com/reports/247086/zinc-flake-coatings-market

👉𝐆𝐞𝐭 𝐢𝐧𝐬𝐭𝐚𝐧𝐭 𝐚𝐜𝐜𝐞𝐬𝐬 𝐭𝐨 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐜𝐨𝐩𝐲: https://www.24chemicalresearch.com/download-sample/247086/Zinc-flake-coatings-market

𝐏𝐨𝐬𝐬𝐢𝐛𝐥𝐞 𝐃𝐢𝐫𝐞𝐜𝐭𝐢𝐨𝐧𝐬 𝐟𝐨𝐫 𝐭𝐡𝐞 𝐏𝐚𝐭𝐡 𝐀𝐡𝐞𝐚𝐝:

Zinc flake coatings market is entering a transformative growth phase as industries seek cleaner, stronger, and longer-lasting corrosion protection systems. With its projected rise from USD 1.53 billion in 2025 to USD 2.27 billion by 2032, supported by a 5.79% CAGR, the market stands positioned for sustained expansion driven by innovation, environmental compliance, and increasing global infrastructure needs. Companies investing in next-generation zinc flake technologies, automation, and sustainable production processes will lead the next decade of growth.

𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐎𝐮𝐫 𝐀𝐝𝐝𝐢𝐭𝐢𝐨𝐧𝐚𝐥 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬:

🔸𝐖𝐚𝐭𝐞𝐫-𝐁𝐚𝐬𝐞𝐝 𝐈𝐧𝐭𝐮𝐦𝐞𝐬𝐜𝐞𝐧𝐭 𝐂𝐨𝐚𝐭𝐢𝐧𝐠 𝐌𝐚𝐫𝐤𝐞𝐭- https://www.24chemicalresearch.com/reports/230920/global-waterbased-intumescent-coating-forecast-market

🔸𝐖𝐚𝐭𝐞𝐫-𝐛𝐚𝐬𝐞𝐝 𝐏𝐫𝐢𝐧𝐭𝐢𝐧𝐠 𝐈𝐧𝐤𝐬 𝐌𝐚𝐫𝐤𝐞𝐭- https://www.24chemicalresearch.com/reports/248261/waterbased-printing-inks-market

🔸𝐖𝐢𝐧𝐝 𝐏𝐨𝐰𝐞𝐫 𝐀𝐝𝐡𝐞𝐬𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭- https://www.24chemicalresearch.com/reports/243381/global-wind-power-adhesive-forecast-market

🔸𝐍𝐢𝐜𝐤𝐞𝐥 𝐀𝐥𝐥𝐨𝐲 𝐏𝐫𝐞𝐬𝐬𝐮𝐫𝐞 𝐕𝐞𝐬𝐬𝐞𝐥 𝐌𝐚𝐫𝐤𝐞𝐭- https://www.24chemicalresearch.com/reports/258605/global-nickel-alloy-pressure-vessel-market

🔸𝐋𝐚𝐧𝐬𝐨𝐩𝐫𝐚𝐳𝐨𝐥𝐞 𝐀𝐏𝐈 𝐌𝐚𝐫𝐤𝐞𝐭- https://www.24chemicalresearch.com/reports/207762/global-lansoprazole-api-forecast-market

🔸𝐖𝐡𝐢𝐭𝐞 𝐊𝐚𝐨𝐥𝐢𝐧 𝐂𝐥𝐚𝐲 𝐏𝐨𝐰𝐝𝐞𝐫 𝐌𝐚𝐫𝐤𝐞𝐭- https://www.24chemicalresearch.com/reports/256635/global-white-kaolin-clay-powder-market

Ishan Barsaiyan

24ChemicalResearch

+ +91 91691 62030

email us here

Visit us on social media:

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.